boda company's iatf16949 quality management system surveillance audit has been successfully completed.

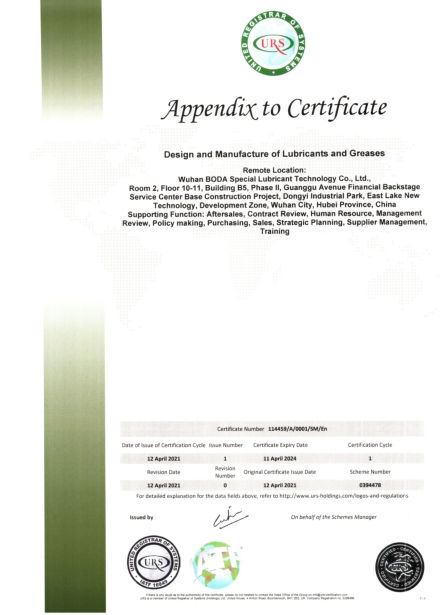

our company first passed the iatf 16949:2016 quality management system audit in april 2021. a year later, on the afternoon of march 30, 2022, the final meeting of the iatf 16949:2016 surveillance audit was held in the boda conference room, signifying the successful completion of the three-day surveillance audit under the supervision of the expert from youkes certification company, mr. dai.

from march 28th to march 30th, boda company welcomed the surveillance audit of iatf 16949 by youkes certification company. during this surveillance audit, various functional departments such as management, production, technology, sales, technical service, general affairs office, and procurement participated in the audit preparation.

mr. dai conducted a comprehensive surveillance audit of boda's iatf 16949:2016 through on-site inspections, document reviews, and interviews. during the audit, he strictly reviewed the manufacturing process of automotive products based on the iatf16949 system standards, combined with boda's internally developed control plans for automotive products, fmea, and pfmea. he also randomly inspected relevant production records, inspection records, test reports, csr (customer specific requirements), product standards, and other related requirements. similarly, mr. dai evaluated and verified the relevant processes of various functional departments (such as management reviews, process audits, product audits, human resources, procurement management, etc.) according to the pdca method and raised four minor non-conformities.

at the final meeting, cao jie, the deputy general manager of boda production, pointed out that the company should attach great importance to the issues identified during this audit, delve into the root causes, and formulate effective corrective measures to continuously improve management levels and ensure the effectiveness of the system operation, laying the foundation for the continuous supply to automotive industry customers.